On Sunday we checked an item off our bucket list: a visit to a Parmesan cheese factory and a Parma ham producer. It was such a busy and exciting day, that I needed a night to process the day before publishing!

There is a cheese Consortium (aka Consorzio del Formaggio Parmigiano-Reggiano) which governs the production of Parmigiano Reggiano cheese, and a Parma ham consortium as well, which governs the quality of the items. The ham producers are privately owned and very wealthy, whereas cheese production is done via co-op. The Consortiums offer free tours Monday thru Friday, but because of our schedule we arranged for a private guide. Paul, Miss M, Big D, Grandma and I were paired for the tour with a couple from California while Papa spent the morning exploring the city of Parma.

First we met our guide, Elena, at the Caseificio San Pier Damiani cheese factory. She works for the Consortium, but does private tours as well. She said there are 5000 farms in the Parma Zone supplying 380 cheese factories. The consortium certifies 3 million wheels of cheese each year.

She told us a lot about the tempermental cows. The milk from cows milked in the summer is not as good as cows milked in winter because of the local grass. It sometimes causes milk to ferment and then the wheels explode. And during the recent earthquake in Parma, the cows were frightened and milk production decreased by 50%.

A “young” Parmesan has rested for 12 months (Paul recalls her saying 18 months), an “old” cheese rests for 12-24 months, and an “extra old” rests for 36 months. According to our guide, most people prefer cheese aged for 24 months since it can be eaten plain or grated. When the cheese is younger, it’s too soft for grating. The cheese has more depth the older it gets.

Only the best Parmesan gets exported. Parma people, and the Consortium, are very concerned about quality and perception. Their cheese is a labor of love. They only want you to buy cheese with the stamped rind since everything else is an imitation.

Here’s a cliff notes version of the process we witnessed:

Cows are milked twice a day starting as early as 3am and then a second time. The milk rests and then the next day it’s skimmed and used for local butter and also fed to the cows. Fresh milk from the day is added to yesterday’s milk plus whey and rennet is added and then cooked. (Parma ham pigs are also fed the whey from the cheese making process.)

We saw it cooking in a large copper vat, and then in another vat they were skimming the whey off the top. All done by hand and feel. No gloves or sanitation codes here!

Then, we witnessed what they call “the birth of the cheese.” We saw them drain the liquid from the large copper vats and lift the cheese out with cheesecloth. It takes two men for this process, since then they split the cheese into two. They call it “the twins” since most cheese wheels have a twin.

The cheese is then wrapped in cloth and put into the mold. It is then transported to a cold room where the cheese wheels are floating in a salt bath for 25 days. Every day, the cheese is turned manually with a stick. How much salt is used? Only nature knows, says our guide. The water and cheese take as much salt as needed (see picture below) and the cheese loses water weight. It starts off in the room weighing 45 kilos, and after the 25 days it weighs between 38-41 kilos.

The cheese is then moved to a holding room. It’s pale in color in the beginning, and then it darkens. Floor to ceiling rounds of cheese and the smell was intoxicating.

After 1 year, the Consortium visits the cheese producer and taps the cheese to see if it’s good, bad, ready, etc. The Consortium people are like “cheese whisperers.” Their only job is to tap the cheese and listen for its readiness. They can tell the density, grain, consistency…all by tapping. If a cheese has problems, stripes are put on the wheel and has to be eaten within 18 months. The Consortium has various seal colors (gold – older,) the Blue pen is used to indicate female or masculine cheese, and for the past several years QR codes have been used to track the cheese.

We could have spent hours watching the people produce the cheese. They work 365 days a year, but only the morning hours. There were three generations living and working in the factory. The floors were wet and slippery, and all the workers wore tall waterproof boots. The grandkids of Bruno Buccello, the elder gentleman working in the factory, were wearing their rain boots too since they wanted to help their Papa make cheese.

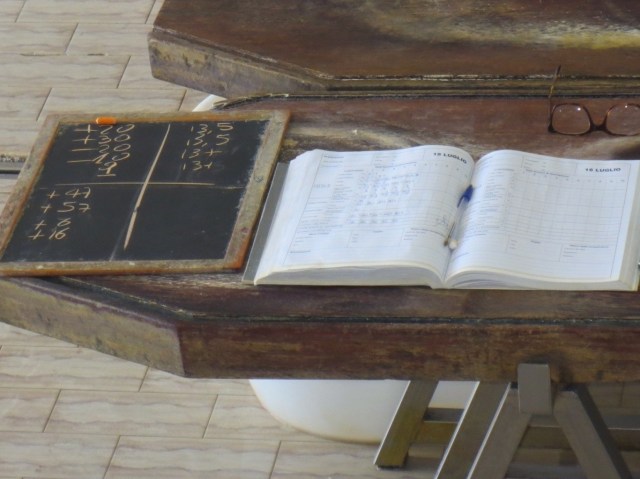

Side note: Grandma and I were surprised by what we would perceive as a lack of sanitation. There are flies everywhere. At one point I saw Bruno scooping a fly out of the liquid in the vats. The light fixtures hanging above these huge vats were filthy covered with dead bugs and cobwebs. And while I understand that part of the process is done by feel, and therefore no gloves are worn, the image of Bruno’s hairy arm going into the vat will forever be imprinted in my mind. There is a daily log book where they record each step of the process…how much milk is used, whey, etc, and the Consortium reviews the book during its visit of the factory.

We then went to another building where we tasted a young and old Parmesan with condiments of honey and a cream balsamic. They also served a bubbly red wine with it which we bought for 4 Euro.

Elena, our guide, had to drag us out of the cheese factory after 90 blissful minutes.

We then went to Zarotti, a yummy patisserie, in the town of Langhirano for a quick espresso, a chocolate filled donut for the kids, and bathroom break. (The bathroom at the cheese producer was a hole in the ground.)

Next stop: tour of a Parma ham producer: Salumificio Massimo. There are 192 factories in the town of Langhirano which make Parma ham Monday to Friday. Similar to the cheese producer, the establishment is family owned, so they live upstairs from the production facility. Elena rang the bell, and the family let us enter their house and then down the stairs to see the 15,000 hams. 15,000 hams may sound like a lot, but this was a very small producer. There are 9-10 million hams made each year in this region.

Here’s the process as Elena explained it to us:

Pigs are kept in a stable and fed, and branded when they are born. At nine months and a minimum of 144 kilos, they are slaughtered and the hind legs are separated and trimmed and branded again. For each pig they make two hams. The legs are then delivered to a prosciutto producer. The legs rest for 24 hours, and then over the next 2-3 days the ham passes through a machine (I dont remember what the machine is for) and the workers manually put salt on the ham near the bone…not on the skin.

The legs then hang on these large racks and they are transported down to the salt cellar (0-4 Celsius) for one week. Each cellar the hams visit are literally cold rooms like giant refrigerators with a large metal door labeled cellar 1, 2, 3, 4. They salt each ham again and put it in salt cellar #2 for two weeks. The ham loses humidity and gets darker after the two weeks.

Then, the hams are washed to remove the salt that had not been penetrated and then they are hung to dry in cellar #4 for one month. I don’t know what happens in cellar #3!

There’s a whole process involving sugna, a fat from pigs kidneys mixed with pepper that is rubbed onto the ham. This process is important as it acts as a kind of “final seal” before the majority of the aging process.

Then the hams spend one year downstairs in aging room. After the year in the aging room, the Consortium comes to visit. Using a porous horse bone needle, they pierce the ham, withdraw the horse bone to smell the quality of the ham, and quickly seal up the hole with the sugna. They repeat this process five times on each ham leg. If the ham is good, they stamp it twice with crowns. It takes approximately 3-6 hours for the Consortium to visit each factory.

Even though the Consortium visits after a year, the prosciutto can be aged up to 30 months. Elena explained that Langhirano is the ideal place for ham production because it’s 100 kilometers from the sea, so the humidity of the air and the hills make a great combination.

After the ham producer, we then followed our guide to Torrechiara, a large castle in Langhirano. We wanted to see the castle, but didn’t tour the inside. We then said farewell to Elena, who remarked that she had never met a boy with the energy of Big D. She took a liking to him and at the ham producer and was telling him stories about a little boy who went into the cellar rooms and turned into a ham.

We headed back to Parma to pick up Papa, and then went to Fidenza Village, an outlet mall with Versace, Dolce &Gabbana, Bruno Magli, Escada and more. I did more shopping at Frette, Furla and Stefanel, and Paul got some nice things at the Armani outlet!

Paul took a few photos of the baptistery, duomo, the river that runs through Parma which dries up in the summer, a cool door in the city, etc.

A perfect day in my book, and the kids did very well with a non-kid-friendly day!

Food report:

Lunch at Zarotti in Langhirano: super thick pizzas topped with hot dog (Paul,) eggplant (Grandma,) plain (Miss M,) and olives + cherry tomatoes (me,) and a ham and cheese panini for Big D.

Dinner at Associazone Corale Giuseppe Verdi which was recommended to us by a friend of a friend who is very knowledgeable of the food scene in Italy. He lives in Italy and I believe writes restaurant reviews for travel guides, but he’s currently in Nepal on another writing project. Anyway, the restaurant has a stage and there’s the occasional opera performance and a memorial to Verdi who was born in Parma. We wanted to try a bottle of white lambrusco which we were told to try and find while in Parma, but the restaurant only carried red. It was a fizzy red wine and not as good as the 4 Euro bottle we had at the cheese producer that morning. For antipasti we ordered “crudo di Parma” with Torta Fritta, which is a salumi plate accompanied by a basket of small rolls which were soft and practically hollow inside like little pillows. The plate had several cuts of meat including ciciolatta which we were all unfamiliar with, so we confirmed the spelling of the meat with the waiter, but I cannot find anything about it online. For primi, Paul ordered the “anolini in brodo” which is a dish unique to Parma — small, round pasta stuffed with veal in a broth. His entree was veal osso bucco with saffron risotto. The restaurant provided breadsticks and pasta with butter which made the kids happy. Grandma had grilled swordfish, and Papa had Filetto di Manzo. I had chinghale with polenta which was very tender. I have never had chunks of chinghale before….only shreds of it in a red sauce over pasta, or in a cured form. The pieces resembled shish kebab in size and were tender except for two pieces which probably had bones in them.

Gelato in Parma a block from the hotel which had many unique flavors such as soya riso, passion fruit, green apple, coconut, kinder pingui and kinder (I assume these tasted like the Kinder bars which are similar to Twix,) fondente (a very rich dark chocolate,) sacher (dark chocolate like a German sacher torte,) zabaione, acai berry, liquirizia (black licorice,) cremino, bacio di dama, galak, cocoa mou, desiderio, graviola, latte di mandorla…no idea what many of those are….plus standard flavors such as amarena, straciatella, fragola, macadamia jazz, pistachio, tiramisu, nutella, caffe, dulce de leche, fior di latte, bacio, menta, cream, cioccolato, melone, banana, fragola (strawberry,) and mango.